Empowering CS International to new highs

Richard Stevenson, CS International Conference Programme Manager and CS Magazine Editor reflects on the April 2023 event.

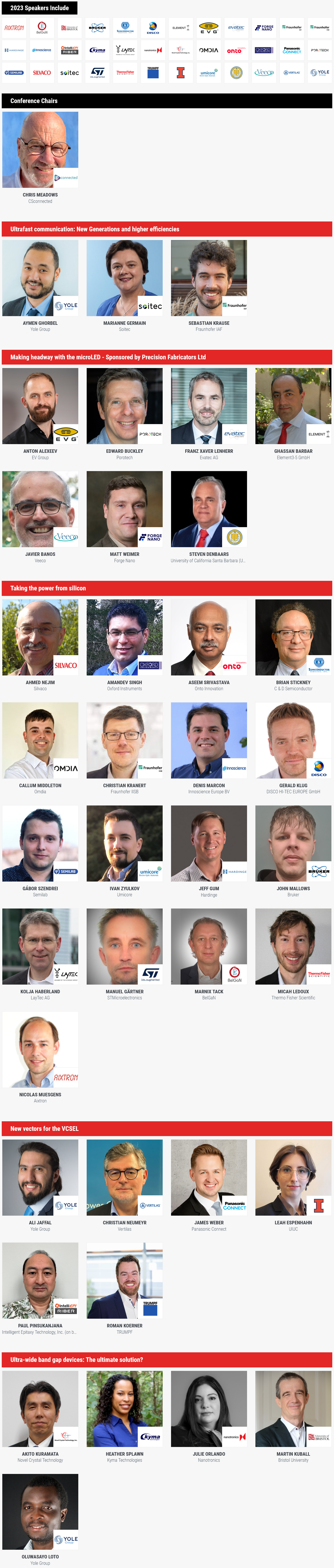

It’s of no surprise that advances associated with the high-volume manufacture of wide bandgap power devices took centre-stage at CS International 2023. With sluggish handset sales providing a headwind to the GaAs microelectronic market and the production of commercial displays based on microLEDs still to really commence, there is good reason why much of the coverage of this two-day meeting, held at the Sheraton Hotel at Brussels Airport on 18-19 April, centred around ramping and improving the production of GaN and SiC power devices and modules.

Both flavours of wide bandgap power electronics are destined to grow at a phenomenal rate throughout this decade, according to Omdia’s Callum Middleton. He shared a forecast showing that the combined sales of SiC and GaN power devices will climb from below $2 billion this year to eclipse $10 billion in 2018 and exceed $18 billion by the end of this decade.

The lion’s share of sales will come from SiC, which is expected to net $16 billion by 2030. As is the case today, the SiC MOSFET will account for the most substantial proportion of sales. Shipments of SiC Schottky barrier diodes will only undergo a modest increase over that timeframe, while sales of full SiC modules will soar, making this the second biggest seller by a significant margin.

The driver behind this exceptional growth is the electric and hybrid electric vehicle, which is predicted to account for more than $10 billion of SiC sales by 2030. Additional revenue will come from numerous applications, with this device being deployed in power supplies, PV inverters, hybrid electric vehicle charging infrastructure, and a variety of military, aerospace and industrial applications.

One of the trends that Middleton has observed is the desire for SiC chipmakers to increase their control over the supply chain, due to high demand for SiC substrates. An example of this is onsemi’s acquisition of GTAT, a company with expertise in making SiC boules.

“Commoditisation of SiC wafers will happen,” remarked Middleton, although this will take time. He added that while there are large capacity expansion plans for SiC wafer production in China, domestic demand will also be high, so initially this additional volume may not support SiC chip production.

For start-ups in the wide bandgap power electronics sector the GaN devices are easier to produce, thanks to the silicon substrate providing the foundation for the epilayers. According to Middleton, compared to the SiC sector, that for GaN has more specialist companies and is less mature.

A substantial player in SiC is the European powerhouse STMicroelectronics. Speaking on its behalf at CS International, Manuel Gärtner, Marketing and Application Director for Wide Bandgap and Electrification for Europe, the Middle East and Africa, made a strong case for why SiC is superior to the silicon IGBT in electric vehicles. The wide bandgap device delivers a gain in efficiency over the IGBT that varies from around 2 percent to 10 percent, depending on load; switching losses plummet by a factor of 7; and switching frequencies can be 5-to-10 times higher. What’s more, thanks to the higher operating temperature of SiC – MOSFETs can run at a junction temperature of 200 °C – engineers can downsize the cooling system by around 80 percent.

Gärtner added that the ongoing shift from 400 V to 800 V for the operation of electric vehicles is enhancing the benefit of SiC over silicon. He claimed that this doubling of the voltage results in a reduction in semiconductor area from a factor of 3 to 5, and a boost in efficiency from 3-5 percent to 8-12 percent.

As well as the increase in SiC revenue coming from a hike in electric vehicle sales, this class of power device, along with its rivals, will benefit from a growth in associated infrastructure. According to Gärtner, for every seven electric vehicles there will be one charger; and for every ten chargers one storage station. Note that once the revolution in transportation is well underway, hundreds of thousands of charging stations will have been built.

Providing a GaN perspective, Denis Marcom, General Manager of Innoscience Europe, outlined plans for the tremendous growth of this company, as well as making a compelling case for this particular wide bandgap semiconductor.

Marcom pointed out that thanks in part to low values for on-resistance and gate-charge, GaN is able to maintain its efficiency at high frequencies. “Compared with silicon and silicon carbide, the recovery time is zero.” This asset enables a shrinking of the size of passive components, and thus a trimming of size, weight and cost at the system level.

According to Marcom, Innoscience boasts the largest GaN capacity worldwide. Last year it could run the equivalent of 10,000 8-inch wafers through its line every month. This capability has enabled the workforce of more than 1500, completely focused on GaN, to have shipped more than 100 million devices – they are a combination of high-voltage products operating at more than 650 V, and variants that are described as medium-voltage (100 V to 150 V) and low-voltage (below 100 V). Shipments are tipped to soar over the coming years as the company undergoes a 7-fold expansion in capacity, realised by 2025.

Many companies offering support to the makers of power devices spoke at the meeting, including those that: provide tools to shape boules prior to processing into substrates; produce MOCVD tools, either with single wafer or multi-wafer capacity; offer metrology techniques to scrutinise substrates and epiwafers; and provide software to aid device design through the simulation of performance. Many of these firms also had a stand in the Exhibition Hall, home to over 80 booths, busy with a record number of delegates.

Mirroring the major trend in the wide bandgap industry, CS International – as well as its co-located conferences, PIC International and Power Electronics International – is on an upward curve, with the next event, to be held at the same venue on 16-17 April 2024, promising to surpass its predecessors.